Where Does Meat Come From?

Not all processing is created equal

When posed with the question “where does meat come from?”, your mind likely jumps to one of two places: either the farm (where your meat originates) or the local butcher shop/grocery store/farmers market (where your meat is purchased). While both of these answers are partially true, there is a piece of the meat system that the average consumer doesn’t think about much (or ever!): the processing facility.

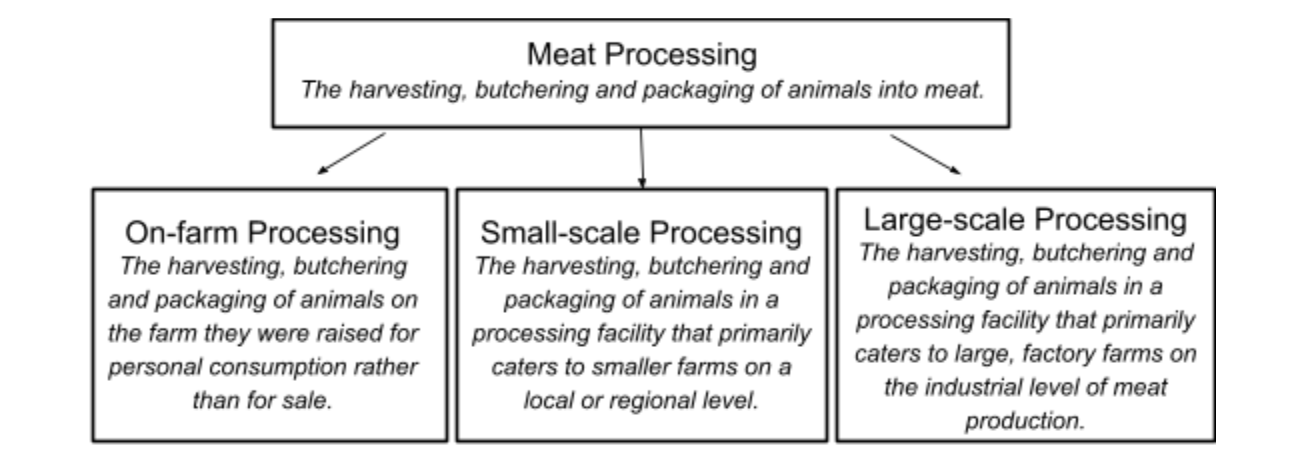

In order to be conscientious consumers who champion local food, it’s important to understand the full scope of our meat system. Everyone knows that something happens in between the farmer raising the animals that become meat, and that meat showing up where we shop in neat and tidy packages, however the specifics of that something are often unknown. Simply put: that “in between'' part of the meat system turns animals into the consumable meat we choose to put on our plates. We call this “meat processing”, and it encompasses the harvesting, butchering and packaging of meat. Since this essential task is so often glossed over, we wanted to take a moment to focus on small-scale processing and the vital role it plays in a better meat system.

You’re probably wondering what exactly constitutes small-scale processing. In the context presented here, it is meat processing at the level in between on-farm processing and large-scale processing.

In other words, small-scale processing is what enables small local farmers to provide us with the option of better meat.

As you may have read about in our blog post, Better Meat in a Pandemic, COVID unveiled the fragility of industrial meat production when the shutdowns of major, large-scale meat processing plants caused meat shortages and wide-spread panic across the country. While this experience was both jarring and unfortunate, it also served as a catalyst, bringing to light some of the major issues within our country’s industrial meat system. More specifically, the severe shortcomings of centralized large-scale meat processing were exposed, highlighting the desperate need for more small-scale processing facilities.

This need is nothing new. In fact, the need for small-scale processing is directly tied to the need for local farmers. For decades, there have been movements dedicated to supporting local food and preventing the disappearance of local food cultures and traditions. These movements have done a great job of encouraging the existence, growth and ongoing improvement of local food systems. Not only have they drawn much deserved attention to the local farmers, chefs and other purveyors of food who grow, create, and sell good food to our communities, but they have also empowered consumers to support those local businesses by making mindful food choices.

The local meat processor, however, is often left out of the concept of “Farm to Table” eating – even though its place in the meat system is just as vital as that of the noble farmer and the empowered consumer. Without the presence of enough sustainable, small-scale processing facilities to provide local farmers with the service of harvesting, butchering, and packaging the animals they raise, the meat from their farms would never arrive at our tables.

The characteristics that differentiate large factory farms from smaller regenerative farms are similar to the characteristics that differentiate large-scale processing facilities from small-scale processing facilities. Much like how the regenerative farming practices of local farms prioritize the health and wellbeing of the land, the people working the land, and the animals themselves to yield a higher quality product in lower quantities, the practices of small-scale processing facilities prioritize humane and ethical harvesting practices and focus on sustainable butchering methods to utilize more and waste less.

Just like in regenerative agriculture, these better practices extend well beyond animal welfare and final meat quality. The impacts of better harvesting and processing practices also directly affect the well-being of the humans working these physically demanding and emotionally taxing jobs. Rather than being subject to the desensitizing conditions of large-scale processing facilities, where quantity is the bottom line and the staff are treated like robotic cogs in a machine, workers in small-scale facilities are considered skilled-trades(wo)men who are experts in their craft and take pride in the fact that they are entrusted to treat each animal with care and respect.

Moreover, many small-scale processing facilities focus on sustainability by utilizing what many large-scale facilities consider to be “waste”, which ultimately benefits both the land and the farmer. Usable by-products like hides, bones, excess fat and organs are saved to be turned into value-added products that the farmer can then sell, and sometimes even the stuff that can’t be turned into products on site (i.e., guts and blood) is turned into compost and returned to the land.

By focusing on quality instead of just quantity, through a higher level of skill and attention to detail in butchery, and using better ingredients in value-added products (like sausage and bacon), small-scale processing facilities also produce end products that are both healthier and tastier.

These practices combined ultimately lead to small-scale processing facilities completing the goals that originated on the farm: to create a nourishing product for the end consumer that honors the land, the hard work of the farmer, and the life and wholeness of the animal, altogether yielding better meat you can feel confident about eating and feeding to your friends and family.

Michelle Cordaro is the owner of Gypsy Butchery, a consultancy focused on facilitating the growth of processing options in America. Passionate about promoting butchery as a skilled trade, she is utilizing her decade of regenerative agriculture, farm-to-table food production and whole-animal butchery experience to guide folks through the ins and outs of opening and running sustainable, niche processing facilities, as well as actively working to help create the next generation of butchers. Follow her on Instagram at @michdaro.